STOLL ProfiLine FS/FZ

STOLLProfiLine FS/FZ

THE MEASURE OF ALLFRONT LOADERS

High end on your farm: Big tractors are on the rise. Of course, at STOLL we also offer the front loaders to go with them. Our ProfiLine Next Generation reliably surpasses the most gruelling tests. Its versatile usability is legendary. It is our pride and joy.CONVINCING BENEFITS FOR YOU

- The various front loader models fit perfectly on tractors from 50 to over 300 hp.

- Best quality fine-grained steel for a front loader with high torsional rigidity and stability.

- The extremely high values for the lifting capacity and height are impressive.

- Z-kinematics and the optimally positioned cross tube provide the driver with the best view of the implement.

- For maintenance work, all you need is a commercially available spanner to get to the lines.

- Best equipment for optional features so you can work with even greater efficiency: Return-to-level, rapid emptying and re-scooping.

- Re-scooping series

- Depending on the loader model, quick release frames are available for other coupling systems – STOLL offers full flexibility

FULL POWER FROM THE START.

German engineering is known all around the world for its high quality, performance and reliability. That is why we develop all STOLL front loaders with precisely these values in Germany. They combine state-of-the-art technology with innovative solutions – and this is exactly what we expect from high-quality German products.

Experience the full power of the STOLL ProfiLine Next Generation. The amazing best values in all areas ensure the highest quality in lifting capacity and lifting height, stability and loading speed. In addition to this, the individually selectable accessories from the ProfiLine Next Generation fit in perfectly with your needs as a farmer or contractor. True professionals for professionals.

FULL POWER – MAXIMUM STABLE CONSTRUCTION.

- The ProfiLine FZ front loaders are made of fine grain steel – Advantage: Highest stability with maximum torsional rigidity at the same time.

- The lifting arm boom is bent from a single piece of steel – The control rods are installed inside the beam. All the hydraulic lines are well protected but can be freely accessed under the beam.

- Kinematics of the entire swing arm body adapted to modern tractors. This results in optimum positioning of the swing arm to relieve the front axle and the best possible clearance for steering angle and axle swing path.

- In order to avoid the need to regularly replace the hose lines by the lifting arms in accordance with DIN 20066, we use wear-free steel hydraulic pipes instead.

A marvel of generations. Drive-in system.

For more than three decades, customers have been able to attach STOLL front loaders to their tractors with ease. Thanks to the drive-in function. The STOLL drive-in system has constantly been further developed for you and functionally optimised. The good news: Despite all the improvements, one thing has remained consistently the same for 30 years: the drive-in principle.

Because we believe it works to your advantage. That’s how your new front loader fits perfectly with our proven console. This system is now part of the basic equipment of all front loaders.

Reliable and used over 1/4 million times! And by the way, it was invented by STOLL. The original from STOLL. Loyal to all generations.

READY TO USE IN UNDER TWO MINUTES:

- When driving in, the front loader slides along the attachment until the locking pin meets the upper end of the connection support

- With the Hydro-Fix all hydraulic lines can be connected to the tractor at the same time. The front loader is lifted slightly to hold the locking pin in position in the catch hook of the connection support.

- The locking lever is pressed downwards and the front loader securely held in position on the attachment. Then the front loader is raised higher.

- The parking stands can be folded in and out without tools.

INTELLIGENT OPERAR:

Ergonomically shaped and easy to handle – everything is under control with the STOLL control units. Customers have lots of requests when it comes to the controls: Some drivers want to work manually and be in control of everything, while other drivers prefer to have an automated control system. Our practical STOLL models offer tailor-made features for every need. Find the right candidate for you.OPTIMUM POSITIONING OF THE IMPLEMENT AT THE PUSH OF A BUTTON

- There is now an end to finding the right position for the implement. Can’t see the setting for the implement in the lowest position? No problem! The implement automatically repositions itself back to the preset position at the touch of a button.

- All it takes is the push of a button – and once the implement is set, it will return to the same position again and again with the selectable level control: This saves on time and patience.

- It is extremely easy to use and works off a mechanical basis: Loosen, adjust and tighten the lever.

- The highlight: Because the return-to-level is integrated into the lifting arms, the driver can always access this function, even if they have mounted the front loader onto another tractor.

- The electric selectable rapid emptying feature is available as standard with the Return-to-Level.

- Clear advantage: Thanks to the automatic levelling and rapid emptying, it is faster and more efficient to load.

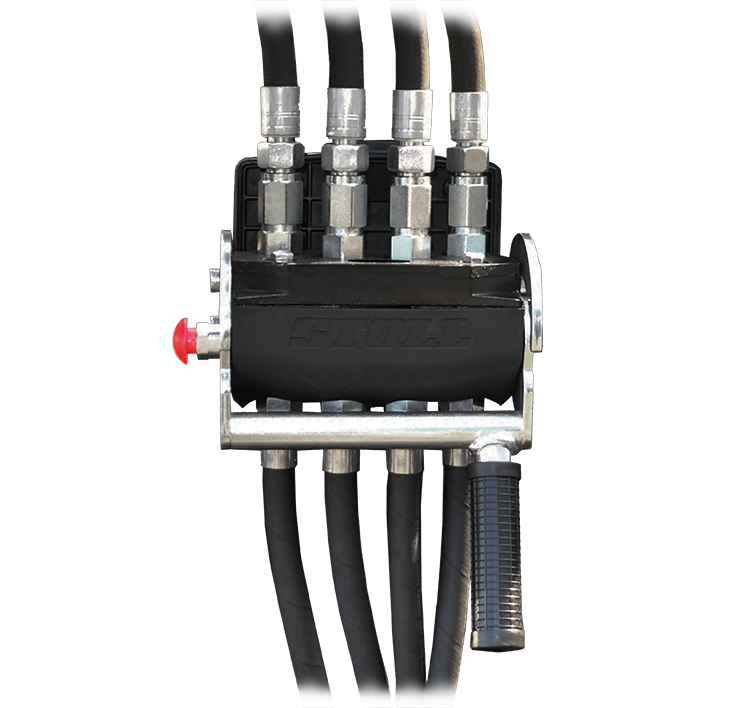

HYDRO-FIX – THE FAST HYDRAULIC CONNECTION.

- All the hydraulic lines can be quickly connected and disconnected – with just one hand.

- The STOLL Hydro-Fix (rectangular, 4-way coupling) can be coupled or uncoupled under high pressure as a standard feature.

- STOLL provides further Hydro-Fixes for common makes of tractors.

- The cover mechanism installed as standard protects the system from large dirt particles. The system must always be kept clean to ensure it works properly.

Etichete: Incarcator, STOLL ProfiLine FS/FZ